In many applications, contactless energy transfer is the best way to supply electric or electronic components.

It can be used to:

- supply components that have been introduced in human body

- load batteries contained in waterproof parts

- avoid contacts to improve reliability (avoids contacts in maritim environnemnt)

- avoid contacts in explosive environnement

- supply moving or rotating components

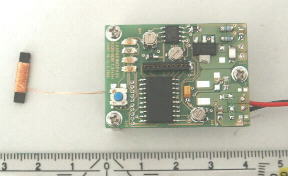

Micro-Beam has developped a low cost contactless energy transfer, based on the cheap MSP430F1101 controller of TI.

Three transformers have been developed:

- A 1.2W transformer with very small secondary parts and cheap componants use to load batteries. Air gap is 1.8mm and efficiency is up to 50%

- A 1.2W transformer using a flexible PCB as secondary instead of coils. Air gap is 2mm and efficiency is up to 50%

- A 50W transformer using directly the net power supply (220V or 110V AC) and coupled with bidirectional data transmission up to 115kbps

50W energy transfer, coupled with data communication

Low cost contactless energy transfer

For this application, size in secondary and price of the whole contactless energy transfer are very important. It is used to load 4.2V batteries with a current of 300mA. The secondary can be contained in a 15x3x0.8mm box (rectifier not included). The primary is based on a MSP430F1101 controller of TI, which cost 0.49$ for rom version.

This transformer includes the following advantages:

- limitation of the loading current of the battery

- presence detection of the secondary, in order to put the transfer in stand-by mode if no secondary is detected

- low data transfer from using energy transfer modulation