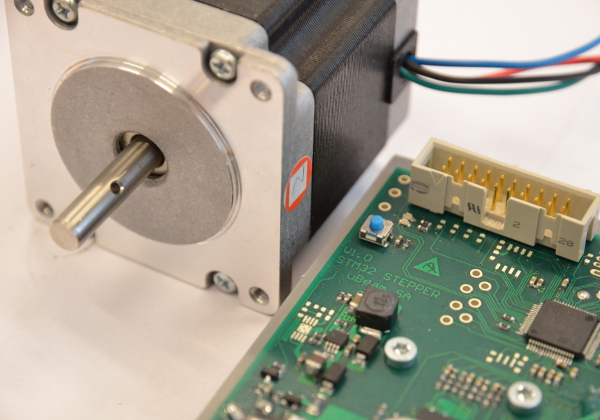

Hybrid stepper Motor are characterized by very high volumic torque compared to Brushless DC motors. Their maximal no load speed is however limited. They can then be a really interesting solution for applications requesting a high torque at low to medium speed.

Micro-Beam offers to control Hybrid stepper motor in close loop with position sensor as well as with the sensorless technology. The advantages of the close loop control are:

- drastically increase the efficiency of the motor (indeed, while controlling the stepper motor in openloop, the supply current is calculated for the worst case load, which means the motor is continuously supplied as it would deliver its maximal torque, while a close loop control allow to adapt the motor current in function of the load).

- increase the robustness of the system by eliminating the stall problems (indeed a brutal increase of load will slow down a motor controlled in closed loop without stalling).

The following video shows some possibilities offered by closed loop sensorless control of a standard stepper motor.

The close loop control can be implemented with sensors, considering Hybrid stepper Motor are characterized a high number of step per turn (around 200). High resolution sensors are then needed to control in close loop such motors. Beside the price of such sensor, this solution is really robust. Really interesting for low speed applications.

To reduce the cost, Micro-Beam proposes a close loop control with the sensorless technology:

- the analysis of the motor phase voltage to indirectly detect the motor position allows to control in close loop a stepper motor with a quite inexpensive solution.

- the last development done in the sensorless technology allows position control, which make possible many applications.

- In order to reduce cost, our drives are able to drive up to 5 stepper motors simultaneously. By that way, the price of the DSP can be divided by 5 for each motor and it simplifies updates of the machines.

|

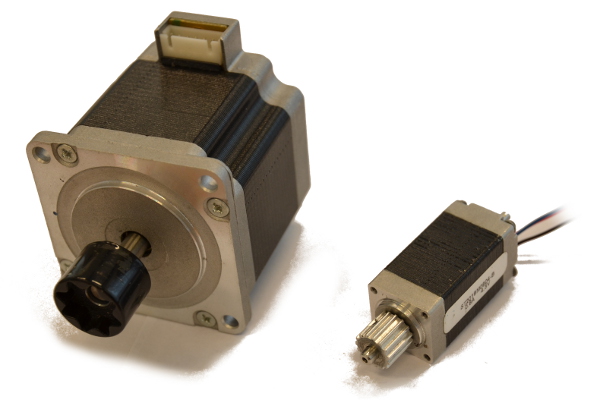

6600 series Hybrid Stepper Motor from Sonceboz |

|

N2300 series from Pittman http://pittmannet.com Permanent torque from 120 mNm (length 38 mm) to 190 mNm (length 76 mm) Maximal speed 10'000 rpm |