Micro-Beam has developed several optimisation programs to design motors and other electromechanical transducers. These programs make use of non-linear optimisation methods in order to reduce the development time and obtain the optimum for a given set of specifications.

Micro-Beam monitors the latest technologies available (magnets, low losses material) in order to always be able to propose a cutting edge design.

A model of the motor or transducer has to be developed and verified. This model can then be integrated in the optimisation software, whichever it might be: Microsoft Excel has a solver that can be used for simple problems, HQP offers more flexibility for large scale problems.

The second step is to define a set of constraints and an objective function, based on the customer's specification and to run the optimisation.

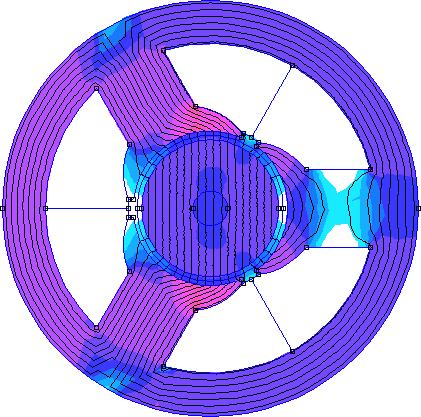

The last step is to verify the design and fine tune it with the use of Finite Elements Simulation tools such as FEMM.

The motor or transducer can then be manufactured.